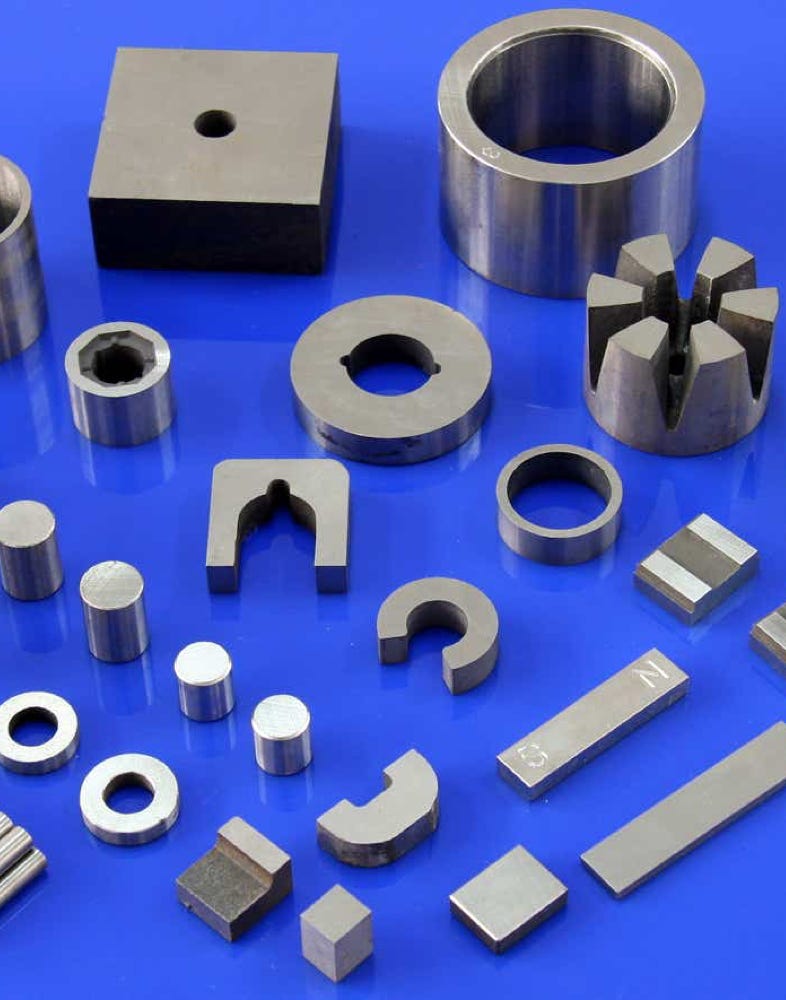

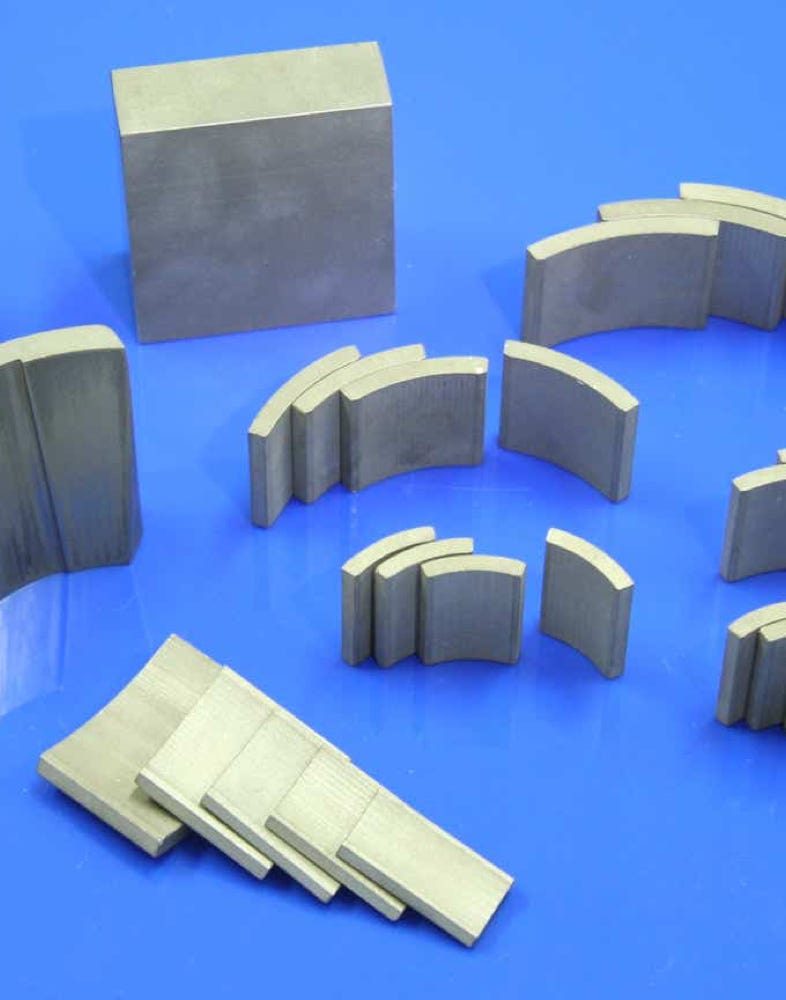

Foresee Group is a premier manufacturer of a wide array of hard and soft magnetic materials. Each material is carefully and skillfully produced in-house. Magnetic materials can be used more than anything else for their magnetic properties. The magnetic response of a material is determined by the magnetic dipole moment associated with its electrons' natural angular impulsive force, or spin. A material's response to an applied magnetic field can be characterized as diamagnetic, paramagnetic, ferromagnetic, or antiferromagnetic.

Alnico’s energy product ranges from 1.0 to 10.0 MGOe. It is produced in both Sintered and Cast. Alnico alloys have the highest Curie temperatures of any magnetic material (around 800°C), Low Temperature Coefficient, and with Operating Temperatures up to 550 °C.

Produced in sintered form in alloys of SmCo5 and Sm2Co17, its energy products range from 18 to 32 MGOe, and Coercivity can exceed 30 kOe. SmCo alloys have low temperature coefficients of induction and coercivity.

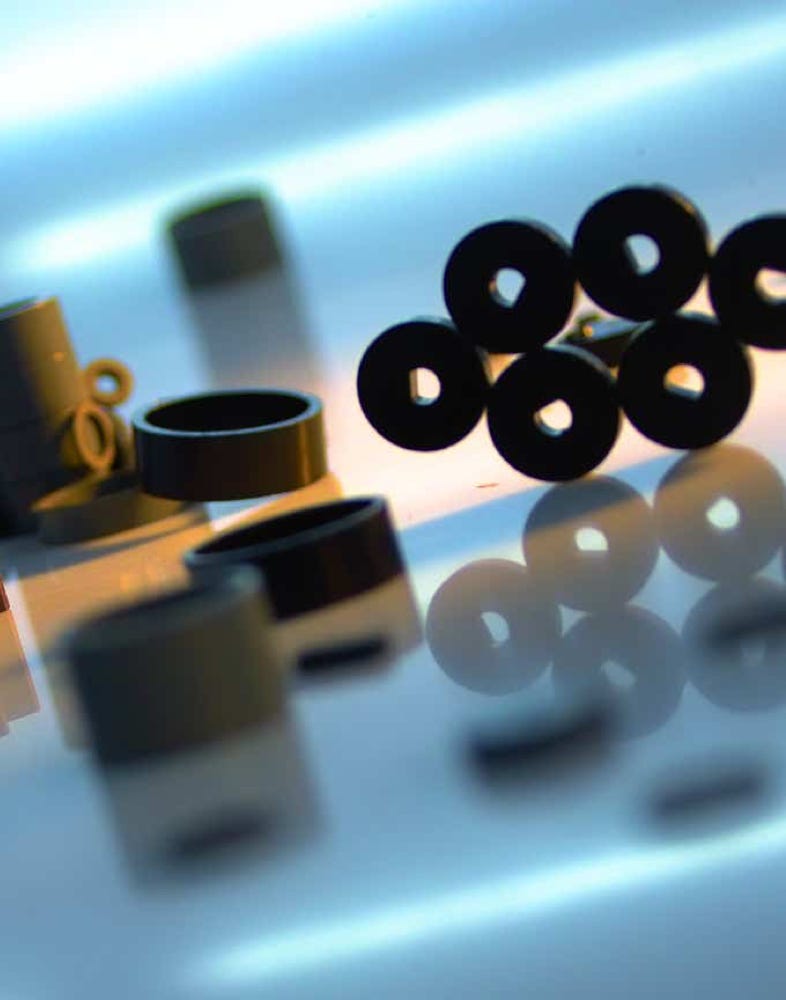

Bonded Magnets are typically manufactured via compression or injection molding processes with NdFeB and Ferrite being the dominant magnetic components. A wide variety of binders are available. They exhibit high structural integrity, high resistance to corrosion and can be formed into complex shapes.

This low cobalt material can be machined as if it was soft steel. The simplified machinability, magnetization with its high working temperature and greatly reduced cobalt content enable it to surpass other permanent magnet materials in many applications.

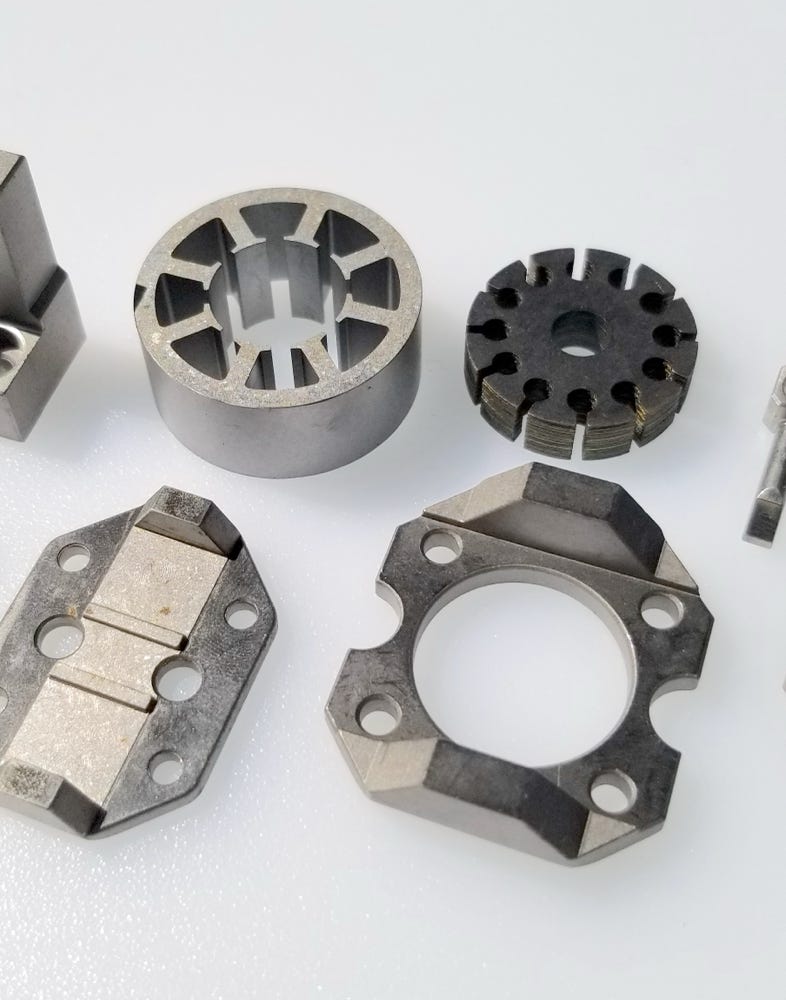

A soft magnetic material can be used as an efficient enhancer of the working flux in a large variety of devices including transformers, generators, motors and power distribution equipment.

MIM offers greater design freedom than most other production processes by freeing designers from traditional size and shape constraints associated with stainless steels, tool steels, soft magnetic alloys, and other materials.

The CIM process produces a nit-shape product that is suitable for high volume production with complex-shaped components and tight tolerances. CIM parts are commonly used in the medical, optical, automotive, and microelectronics industries. Moreover, it is also used in industries that requires complex geometries, different profiles, wall thickness and undercuts.

Foresee Group offers expertise in the research, development and application of all magnetic materials, alloy parts and more.

Magnetic assemblies are units combining permanent magnets with magnetic and/or non-magnetic components to create a magnetic field in a given space or a strong holding force than a monolithic magnet of the same size. Our automated assembly lines are designed to factor in costs, establish production efficiencies and high quality, reduce or eliminate variability in each assembly and improve safety for employees.

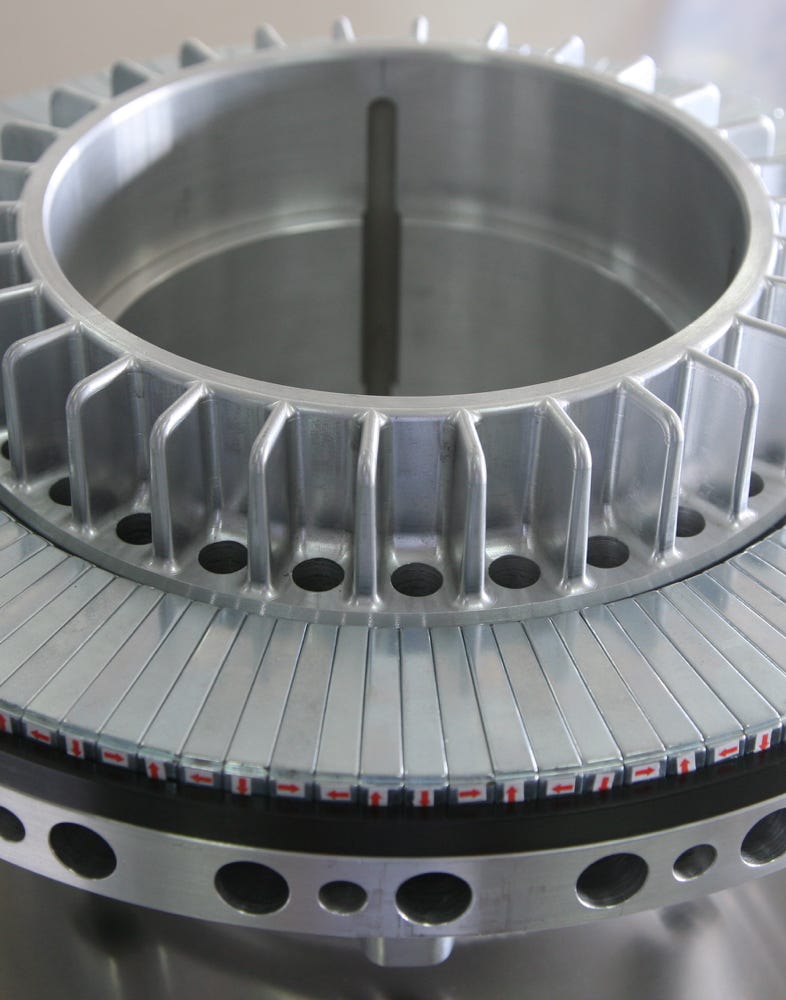

Magnetic modules are products or semi-finished products that realize the application function after magnetic materials are assembled with other materials. It is widely used in motor stators and rotors, sensors, filters, jacks, magnetic separators, magnetic pumps, speakers, and other products or devices.

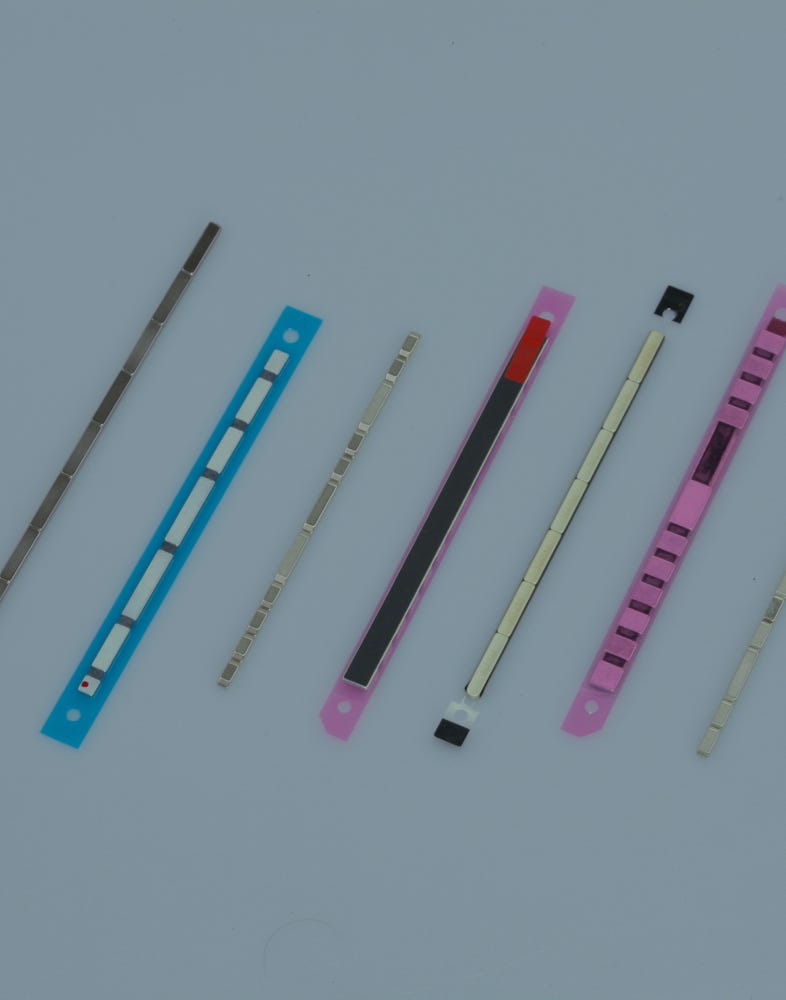

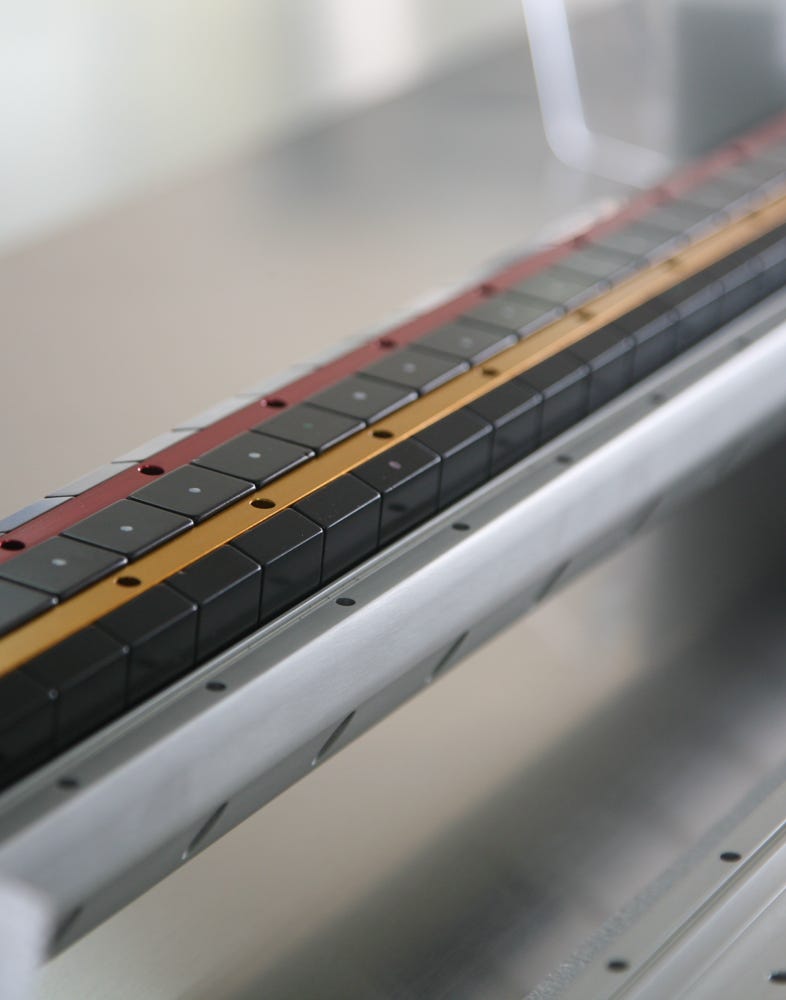

The Halbach arrays are a magnetic assembly that enhances the magnetic field on one side of the array and reduces it on the other. Halbach arrays provide higher fields than magnets of the same size.

Magnetic sub-assemblies are units combining permanent magnets with magnetic and/or non-magnetic parts to be the interface with other components in the finished product. These assemblies are integral components of motors, smartphones, generators, radar, computers, and a vast array of other devices.

Magnetron sputtering is a high-vacuum coating technique that creates high-density films with superior adhesion to the substrate that confine the plasma near the surface of a target. This enhances deposition rate and boosts the usage efficiency of the target material.

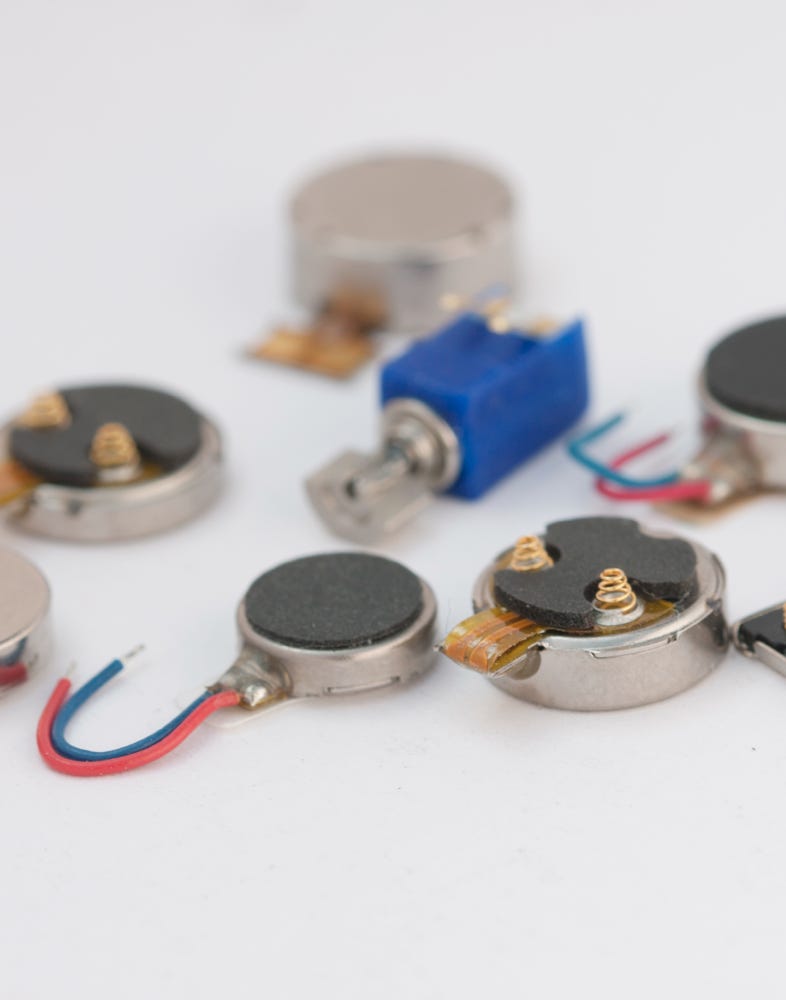

Haptic motors are used to create vibratory feedback and notification in consumer electronic devices. Vibration is generated through rotating an unbalanced mass or linearly oscillating a mass undergoing simple harmonic motion between springs.

Haptic modules are the essential components in compact audio systems, where permanent magnets generate the magnetic field that causes the voice coil to oscillate when an AC excitation current is applied.

Permanent magnet motors are a type of brushless electric motor that uses permanent magnets. It is more efficient than traditional induction motors or motors with field windings for specific high-efficiency applications such as electric vehicles.

We use cookies on this site to enhance your user experience.

Please see our Privacy Policy for details. By clicking “OK”, you are giving your consent for us to set cookies.

OK