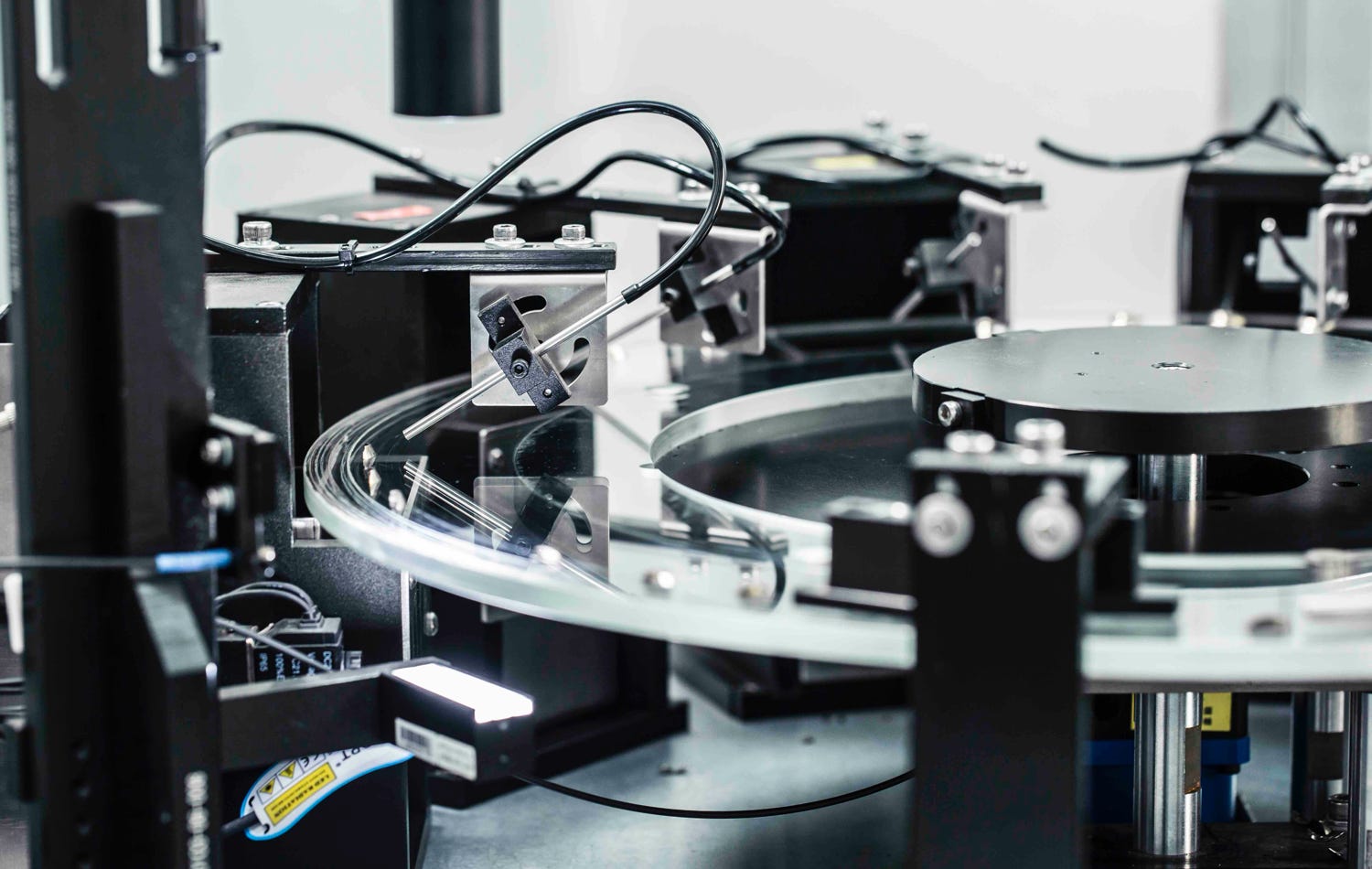

Integration

Our experienced team of engineers and manufacturing capabilities has the know-how to put automated systems into place quickly, correctly, and with the customer requirements in mind.

Automation provides operational stability and statistical process control. Foresee Group creates, develops, and places automation technology into most of our processes, including assembling, magnetizing, testing, and packaging. Process automation allows us to produce high-volumes of parts more quickly with consistent quality and accuracy, this also allows delivery schedules to be met more easily. Process deviation trends are used to realign production processes with statistical control limits. With experiences in integrating lean manufacturing, Foresee Group designs and implements systems that continually meet the need and demand of our customers.

Precision Magnet Assemblies

Magnetizing System

Measuring System

Automation in Packaging

Motor Assemblies

We use cookies on this site to enhance your user experience.

Please see our Privacy Policy for details. By clicking “OK”, you are giving your consent for us to set cookies.

OK